Handling operations for power outage accidents in glass melting furnaces

For glass factories, they must have a dual-circuit power supply system and be equipped with emergency battery packs, diesel generator sets and other equipment; the battery packs should be able to supply power to equipment that cannot be powered off under any circumstances at any time, such as full-line operation control systems, fuel And gas supply system, safety lighting system, alarm system, monitoring and inspection system, edge puller motor and annealing kiln motor, gate motor control system and other equipment; the diesel generator set mainly supplies power for equipment that keeps the kiln from being damaged. Such as cooling air system and cooling water system, reversing operating system, batch material supply system, tin bath heating and cooling air system, power storage unit, etc. This system can only provide temporary power. If the power outage lasts for a long time, the feeding and fuel supply must be stopped, and the furnace temperature must be appropriately lowered to protect the kiln.

When there is a power outage, the computer will automatically detect it and automatically switch the power supply line after about 1 second. Most devices will function normally. As a melting furnace, you must first start the fan to ensure that the pool wall cooling air, steel ballast cooling fan and combustion-supporting fan are in operation. Otherwise, the steel structure will soften under high temperature, which will cause fatal consequences to the furnace. In this case, the fan in the furnace control room should first be manually controlled and the remote control should be switched to local control.

Handling operations for power outage accidents in melting furnaces:

(1) Regardless of whether it is an instantaneous power outage or a long-term power outage, once a power outage occurs, the main power valve should be pressed to prevent excessive current from burning out the fuse after the call comes.

(2) Open the natural ventilation cover to ensure combustion progress.

(3) When the liquid level drops and production cannot be guaranteed, manual feeding must be organized, and broken glass clinker can be added.

(4) Kiln operators should be distributed around the kiln and under the kiln to observe relevant conditions in a timely manner, especially the pool wall, to prevent leakage of glass water.

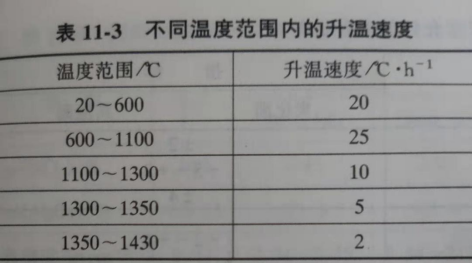

(5) After the power supply is restored, first turn on the combustion-supporting air to ensure normal combustion. If the temperature drops too much, it should be gradually raised to the normal operating temperature, and the kiln protection fans should be turned on one by one. The air volume should be gradually increased to prevent excessive blowing. Bricks exploded.

(6) Turn on the feeder and feed the material slowly. Do not chase the liquid level too fast to prevent the material mountain from being too far away and causing accidents such as material running out.

-

Silicate fire brick

Silicon thermal insulation refractory brick refers to the thermal insulation refractory products made of silica as the main raw material, with a SiO2 content of no less than 91%. In addition to the heat insulation perfor··· -

silica bricks manufacturing process

1.1 Determination of raw material ratio and particle compositionThe raw materials for making silica bricks are silica and waste bricks containing more than 96% SiO2, in addition to lime, mineralizers and organic binders.··· -

Alumina hollow ball bricks

Alumina hollow ball bricks are made of alumina hollow balls and alumina powder as the main raw materials, combined with other binders, and fired at a high temperature of 1750 degrees. It belongs to a kind of ultra-high t··· -

Anti-stripping high alumina brick for cement kiln

Anti-stripping high alumina bricks are made of high alumina bauxite clinker, mullite, kyanite, zircon sand, and binder first through granulation and powdering processes, mixed in a certain proportion, then pressed into s···