Selection and operation measures of patching refractory bricks in glass melting furnace

Brick patching is a common method to extend the life of pool walls. In the melting area, the better domestic pool wall refractory bricks need to be tied to the upper part of the pool wall 2 to 4 years after they are put into operation. After that, the bricks are tied once every 1 to 2 years on average until the kiln is shut down for cold repairs. Imported No. 41 oxidized non-shrinkage zirconium corundum bricks from French Sipu Company can ensure that the pool wall bricks will be tied with bricks after 3 to 5 years of operation. For example, the tank wall of a domestic 600t/d float kiln adopts No. 41 from French Sipu Company. After the No. oxidation method, the shrinkage-free zirconium corundum bricks were put into operation for 3 years and 2 months before the bricks were tied.

Appropriate measures must be taken when patching Bricks to ensure that the tied pool wall bricks do not explode and extend the life of the pool wall bricks. The general approach is to use a heating box to heat the pool wall bricks until the temperature of the bricks reaches about 600°C, then use special tools to take them out on site and tie them to the corresponding position to fix them. In this way, the tied bricks will not explode, the brick tied efficiency is high, and the tied pool wall bricks can run for 2 years. Some glass factories do not use a heating box for heating, but simply bake the bricks on the edge of the kiln. After baking, the temperature of the pool wall bricks will not exceed 200°C, and then they are tied. This can easily cause the bricks to burst, waste materials, and increase the workload of the operators. At the same time, the tied bricks will also crack due to the large temperature difference between the inside and outside, affecting the life of the bricks. Generally, they need to be tied again after one year.

In the middle and later stages of the furnace, when the thickness of the pool wall is very small, bricks can be tied to the pool wall. Considering the characteristics of fused bricks, No. 33 or 36 oxidation method non-shrinkage zirconium corundum bricks are generally used, with a specification of 300mm×400mm×100mm, and are tied from the No. 1 small furnace to the pool wall of the hot spot small furnace. Each time bricks are tied and the air volume of the pool wall is appropriately increased, it can generally be used safely for about 2 years. Bricks can generally be tied 2 to 3 times in one kiln period. When the tied bricks conflict with the steel structure of the kiln, they cannot be tied again. You can use the method of removing the original tied bricks and retying them. At this time, you should consider temporarily lowering the liquid level to ensure safety and avoid glass water leakage.

Considering the matching with the steel structure of the large kiln, the thickness of the above-mentioned binding bricks is generally 60~80mm depending on the purpose of the kiln.

On some float glass furnaces, sintered dense chrome bricks are used to tie the bricks, and very good results have been achieved. For example, the tank wall of a 500t/d float kiln in a float glass factory in Guangdong is made of sintered dense chromium bricks, and the furnace life is extended to 14 years; the tank wall of a 600t/d float kiln in a float glass factory in Dalian is made of sintered dense chrome bricks. patching Bricks also greatly increases the age of the kiln.

-

Silicate fire brick

Silicon thermal insulation refractory brick refers to the thermal insulation refractory products made of silica as the main raw material, with a SiO2 content of no less than 91%. In addition to the heat insulation perfor··· -

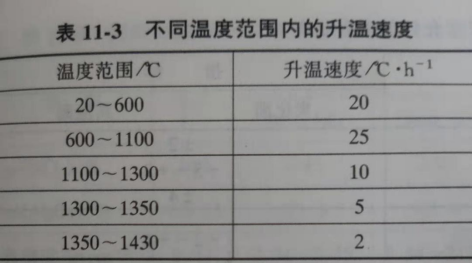

silica bricks manufacturing process

1.1 Determination of raw material ratio and particle compositionThe raw materials for making silica bricks are silica and waste bricks containing more than 96% SiO2, in addition to lime, mineralizers and organic binders.··· -

Alumina hollow ball bricks

Alumina hollow ball bricks are made of alumina hollow balls and alumina powder as the main raw materials, combined with other binders, and fired at a high temperature of 1750 degrees. It belongs to a kind of ultra-high t··· -

Anti-stripping high alumina brick for cement kiln

Anti-stripping high alumina bricks are made of high alumina bauxite clinker, mullite, kyanite, zircon sand, and binder first through granulation and powdering processes, mixed in a certain proportion, then pressed into s···